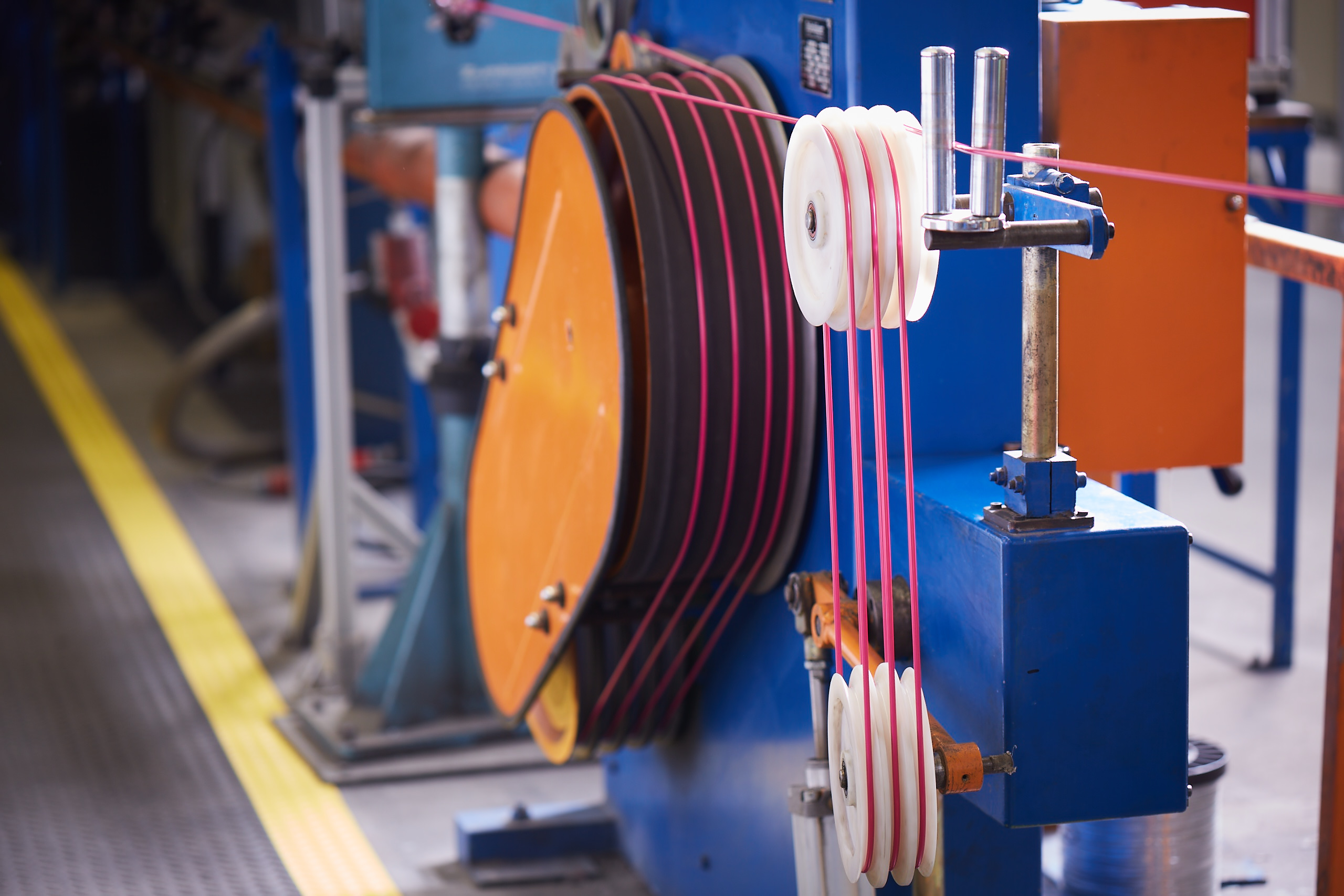

Extrusion – Coated steel cables

Protection and signaling effect with the right sheath for your wire rope

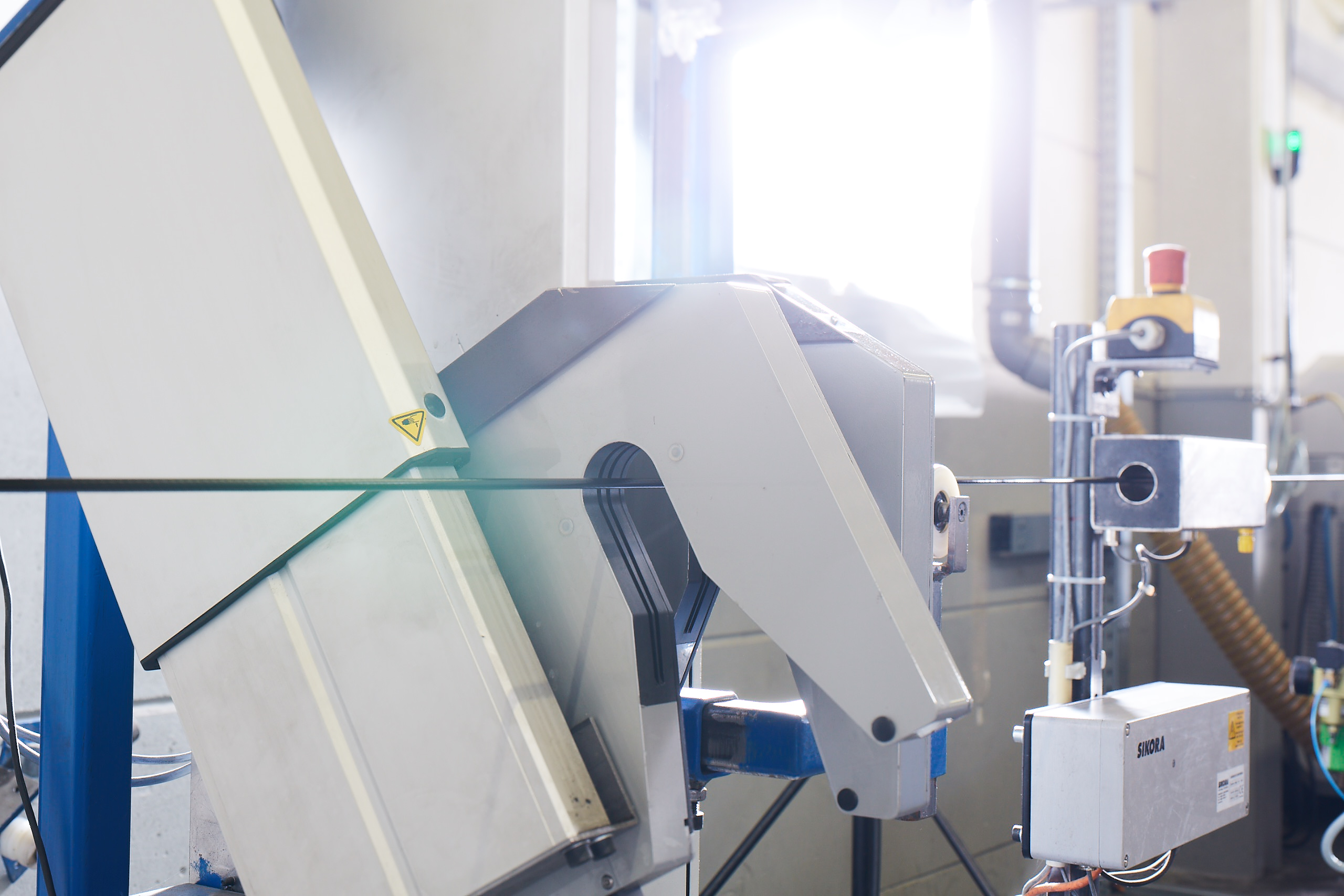

The processing of plastics requires a high degree of precision in the tools and machine settings as well as in-depth knowledge of the specific properties of the materials. As an extrusion specialist for steel cables and other long products such as wires and fiberglass rods, we offer a wide range of services. With our expertise and flexibility in production, we support you in finding the ideal sheathing for your specific needs.

Covered wire ropes for various requirements

We offer high-quality coated wire ropes by the meter that are suitable for a wide range of applications. Our products are available in diameters from 0.5 mm to 22 mm, covering a wide range of standard dimensions. In addition, we are able to manufacture both round cross-sections and special dimensions according to specific customer requirements and to attach accessories such as thimbles, eyelets and hooks.

Our sheaths are made from various high-quality plastics such as PVC, PE, PA, PU or PP in order to offer optimum adaptation to the respective application conditions of the wire rope. You can also choose the right color from our stocked range or specify an individual desired color to ensure perfect adaptation to your area of application or corporate design.

Choosing the right plastic

The following descriptions of the plastics on offer are intended to provide an overview of the advantages and areas of application. We would also be happy to advise you on selecting the right plastic for your application.

Polyamide coating

The polyamide (PA) coating reliably protects our wire ropes against mechanical influences and corrosion. Our coated steel wire rope is particularly suitable for use in maritime environments, the food industry and for medical applications. Compared to PVC, PA is significantly more resistant and is the preferred choice for use with pulleys in particular, such as our fitness ropes for sports facilities. Thanks to their excellent wear resistance, our sheaths with PA guarantee a long service life.

Polyethylene coating

A wire rope sheathed in polyethylene (PE) is flexible to handle and resistant to moisture and chemicals. Thanks to these properties, the sheath offers optimum protection and durability for wire ropes in demanding environments. Our coated wire ropes are particularly suitable for use in the water industry, where they can withstand corrosion and water loads.

Polypropylene coating

Polypropylene (PP) coated wire ropes are characterized by their exceptional lightness and high abrasion resistance. The smooth surface of PP minimizes friction losses, which improves the handling and efficiency of the ropes. In addition, PP offers good resistance to UV radiation, so that the wire ropes retain their performance even during prolonged outdoor use. These properties make coated PP wire ropes ideal for marine, construction and agricultural applications, where they are resistant to pesticides and fertilizers.

Polyurethane coating

Polyurethane (PU) offers excellent resistance to oil, grease and many chemicals, making the ropes ideal for industrial applications. The smooth and resistant surface of PU reduces friction and minimizes wear. In addition, the flexibility of PU is maintained even at low temperatures to enable use in cold environments. Thanks to these properties, coated wire ropes with PU are particularly suitable for applications in mechanical engineering and in demanding outdoor environments.

Polyvinyl chloride coating

Sheathed wire ropes with polyvinyl chloride (PVC) are weather-resistant and durable. The coating provides excellent insulation properties, which protects the ropes from electrical influences and makes them safe to use. The plastic is also resistant to moisture and chemicals, making them ideal for use in damp or aggressive environments. Sheathed wire ropes with PVC are therefore particularly suitable for applications in the construction industry, electronics and outdoor areas where reliability and protection are of the utmost importance.

FAQs – frequently asked questions about coated steel wire ropes

Contact us

Would you like more information about our production or do you have questions about our products? Would you like to find out more about our accessories? Simply get in touch with us – we look forward to hearing from you!

Hamburger Drahtseilerei

Hamburger Drahtseilerei A. Steppuhn GmbH

Klaus-Groth-Straße 15

D-23843 Bad Oldesloe

+49 (0) 4531 / 8990 – 33